PVC waxaa laga soo saaray chloride vinyl iyadoo la adeegsanayo polymerization xagjirka bilaashka ah.Polymerization-ka-joojinta, emulsion polymerization iyo polymerization bulk, polymerization hakinta waa habka ugu muhiimsan, xisaabinta qiyaastii 80% wadarta wax soo saarka PVC.Warshadaha, habka wax soo saarka PVC guud ahaan wuxuu ku salaysan yahay habka loo helo monomer vinyl chloride si loo kala saaro, waxaa loo qaybin karaa habka calcium carbide, habka ethylene iyo soo dejinta (EDC, VCM) monomer habka (caado ahaan loo yaqaan habka ethylene iyo habka monomer dibadda laga keeno) .Marka loo eego hababka wax soo saarka ee kala duwan, budada PVC waxay u qaybsan tahay: xuubka PVC ee caalamiga ah, resin PVC oo leh heer sare oo polymerization ah, iskutallaabta PVC.Xabagta PVC ee caalamiga ah waxaa lagu sameeyay polymerization of vinyl chloride monomer iyadoo hoos timaada ficilka bilawga;Xabagta PVC oo leh heer sare oo polymerization ah waxaa loola jeedaa resin-ka la sameeyay iyadoo lagu darayo wakiilka sii kordhaya ee nidaamka polymerization ee vinyl chloride monomer;Xabagta PVC ee isku-xiran waa xabagta laga sameeyay iyadoo lagu darayo wakiilka iskutallaabta ah ee ka kooban diene iyo polyene ee nidaamka polymerization ee vinyl chloride monomer.

Hakinta resin polyvinyl chloride Qaabka hadda:

Sg-1: K 77-75 celceliska darajada polymerization

Sg-2: K 74-73 celceliska darajada polymerization

Sg-3: K qiimaha 72-71 Celceliska darajada polymerization 1350-1250

Sg-4: K qiimaha 70-69 celceliska darajada polymerization 1250-1150

Sg-5: K qiimaha 68-66 Celceliska darajada polymerization 1100-1000

Sg-6: K qiimaha 65-63 Celceliska heerka polymerization 950-850

Sg-7: K qiimaha 62-60 celceliska heerka polymerization 850-750

Sg-8: K qiimaha 59-55 celceliska heerka polymerization 750-650

Codsiyada ugu muhiimsan:

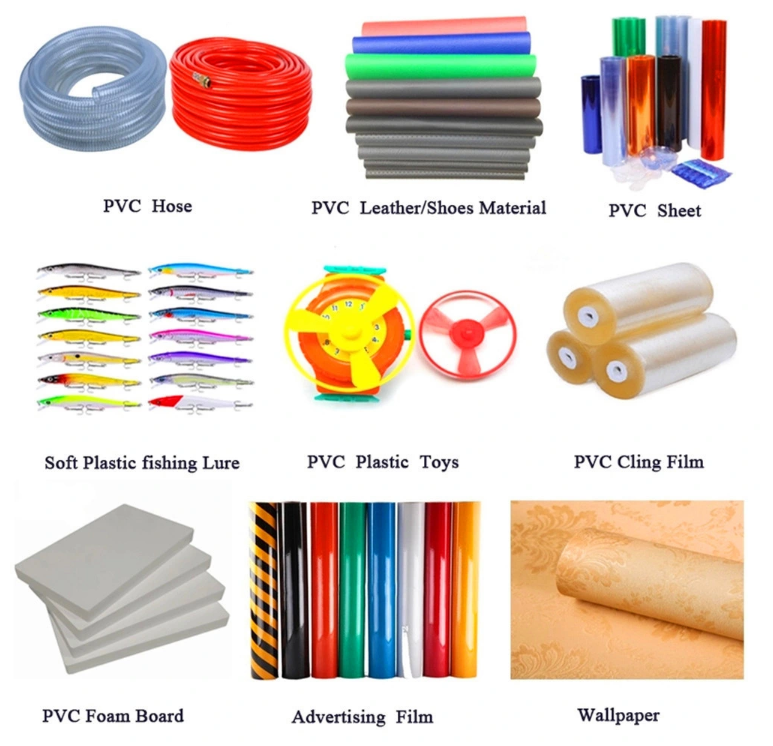

Xabagta PVC waxaa lagu farsameeyaa noocyo kala duwan oo baco ah, sida ku cad isticmaalkeeda waxaa loo qaybin karaa laba qaybood oo ah alaab jilicsan oo adag, inta badan loo isticmaalo soo saarista qaybo hufan, tuubooyinka tuubooyinka, kaararka dahabka, qalabka dhiig-shubidda, jilicsan iyo adag. tuubooyinka, taarikada, albaabada iyo daaqadaha, profiles, filimada, qalabka dahaarka korontada, galka fiilada, walxaha dhiigga lagu shubo, iwm.

1.PVC guud ahaan jilicsan iyo alaab adag - iyadoo la isticmaalayo extruder waxaa lagu tuujin karaa tuubooyinka jilicsan iyo kuwa adag, fiilooyinka, fiilooyinka, iwm.;Mashiinka qaabaynta duritaanka iyo caaryada kala duwan, waxaa laga samayn karaa kabo caag ah, lugaha, dacas, alaabta carruurtu ku ciyaarto, waxyaabaha maalinlaha ah loo baahan yahay iyo baabuurta iyo qalabka korontada.

2 PVC tuubo adag iyo profile - marka loo eego caagadaha kale, PVC caabbinta gabowga waa mid aad u fiican, xoogga saameynta sare iyo adkaanta, qiimo jaban, oo ku habboon tuubooyinka dheecaanka iyo tuubooyinka kale ee dhismaha, iyo profile profile.

3 Filimka PVC - PVC iyo waxyaabaha lagu daro isku dhafan, balaastiigga, isticmaalka saddex ama afar qaab duuban oo duuban oo dhumucdiisuna tahay filim hufan ama midab leh, oo leh habkan habka filimka, waxay noqdaan filim caleenta.Sidoo kale waa la gooyn karaa, bacaha baakadaha kuleyliyaha, jaakadaha roobka, dharka miiska, daahyada, alaabta lagu ciyaaro ee la buufiyo iyo wixii la mid ah.Filim hufan oo ballaadhan ayaa loo isticmaali karaa aqalka dhirta lagu koriyo, aqalka dhirta lagu koriyo ee caagga ah iyo filim caag ah.Ka dib fidinta labada jiho ee filimka, hantida kuleylka kulaylka, ayaa loo isticmaali karaa baakadaha la yareeyo.

4 badeecooyinka dahaarka leh ee PVC - oo leh substrate maqaar macmal ah ayaa PVC ku wareersan maro ama warqad, ka dibna 100 darajo Celsius oo ka sarreeya caag ah.Waxa kale oo ay noqon kartaa PVC iyo filimka calending kaaliyaha ah, ka dibna wada riixaya substrate ah.Maqaarka macmalka ah ee aan lahayn substrate si toos ah ayaa mashiinka calending u dhejiyaa dhumuc gaar ah oo xaashi jilicsan, ka dibna lagu cadaadiyo qaabka.Maqaar macmal ah ayaa loo isticmaali karaa in lagu sameeyo shandad, bacaha, daboolka buugaagta, fadhiga fadhiga iyo barkimada baabuurta, iyo maqaar sagxadda, oo loo isticmaalo sida qalabka dhismaha.

5.PVC alaabada xumbo - isku dhafka PVC ee jilicsan, ku dar qadarka saxda ah ee wakiilka xumbo si aad u sameyso walxaha xaashida, dhejinta xumbo balaastigga, kabaha xumbo, kabaha, kabaha, iyo alaabta baakadaha baakadaha aan shoogga lahayn.Waxa kale oo aad u isticmaali kartaa FOUNDATION extruder xaashida PVC ee adag xumbo hoosaysa, waxay bedeli kartaa tijaabada alwaax, waa nooc cusub oo qalabka dhismaha ah.

6 xaashida hufan ee PVC - PVC waxay ku dartaa wax ka beddelka saamaynta iyo xasiliyaha, ka dib marka la isku daro, balaastiig, calending oo noqo xaashi hufan.Isticmaalka samaynta kulul waxaa laga samayn karaa weelal hufan oo dhuuban ama loo isticmaali karaa baakadaha finan vacuum ah, waa alaabta baakadaha fiican iyo alaabta qurxinta.

7 saxan adag oo PVC ah iyo saxan - xasiliyaha PVC, saliidaha iyo buuxinta, ka dib marka la isku daro, oo leh extruder waxaa lagu faafin karaa caliber kala duwan oo ah tuubo adag, tuubo qaabaysan oo gaar ah, gogosha, loo isticmaalo sida tuubada hoose, tuubada cabitaanka, gacmaha siliga ama jaranjarada gacanta.Isku darka kululaynta xaashida caleenta ah waxay samayn kartaa go'yaal adag oo dhumucyo kala duwan leh.Saxanka waa la gooyn karaa qaabka la rabo, ka dibna isticmaalka qalabka PVC ee leh alxanka hawada kulul ee noocyo kala duwan oo kiimiko ah oo u adkaysta taangiyada kaydinta, dhuumaha hawada iyo weelasha.

8.PVC kale - albaabada iyo Daaqadaha ayaa laga sameeyay qalab adag oo qaabaysan.Waddamada qaarkood waxay lahaayeen albaabbada alwaax iyo daaqadaha aluminiumka iyo albaabada kale ee caadiga ah iyo suuqa daaqadaha;Qalabka alwaax ku dayashada ah, qalabka dhismaha birta ee jiilka (waqooyi, dhinaca badda);Weel madhan.

Waqtiga boostada: Agoosto-08-2022